Exploring Imperfect Precision

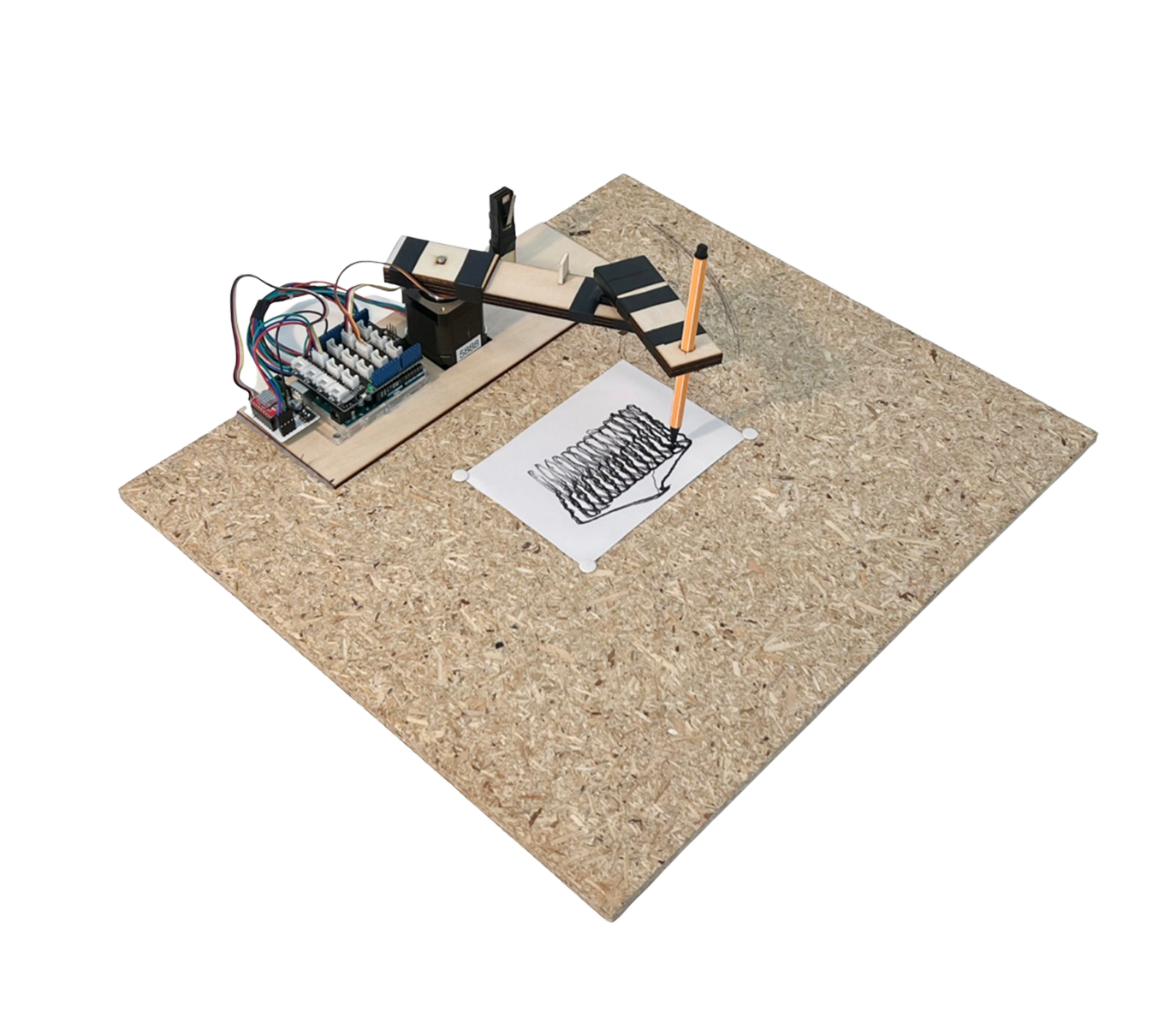

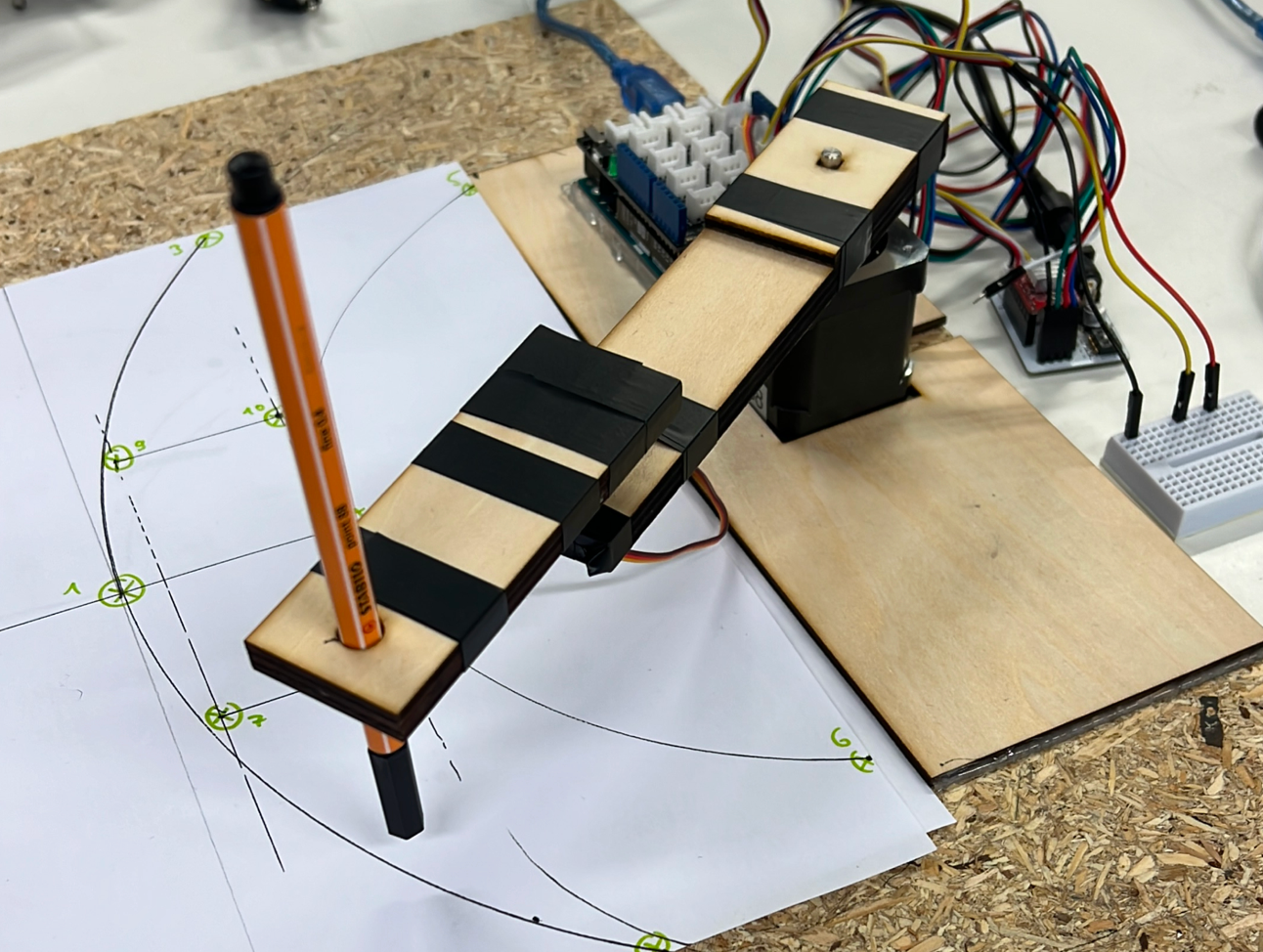

In a one-week mechatronics workshop, we built a two-joint drawing arm inspired by human movement. Rather than focusing on perfect precision, the project explores how mechanical systems can produce organic, imperfect, and almost hand-drawn line qualities.

System Control

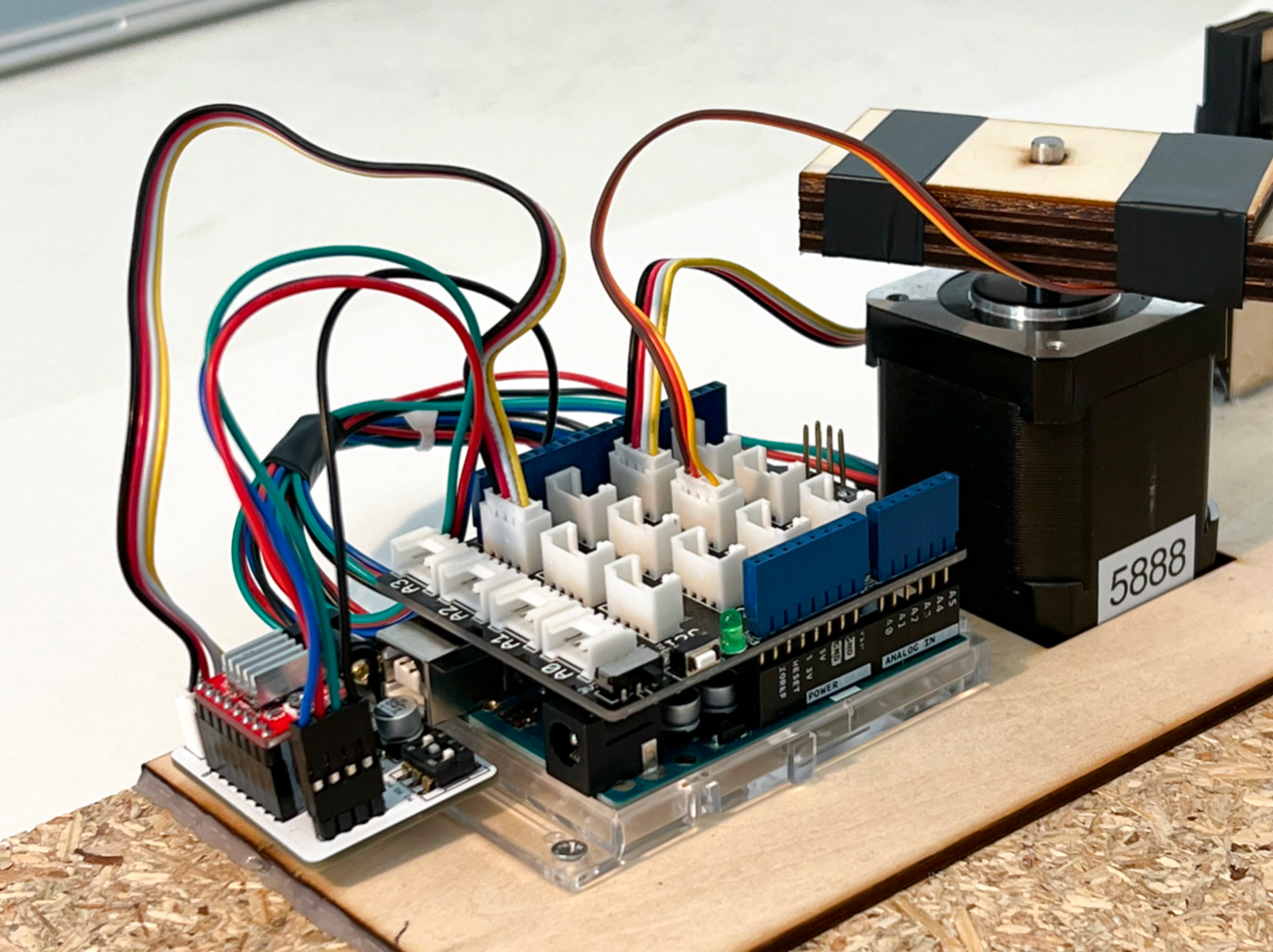

The system was controlled using an Arduino in combination with stepper and servo motors. This setup allowed precise coordination of the arm's joints while still leaving room for natural variation in movement.

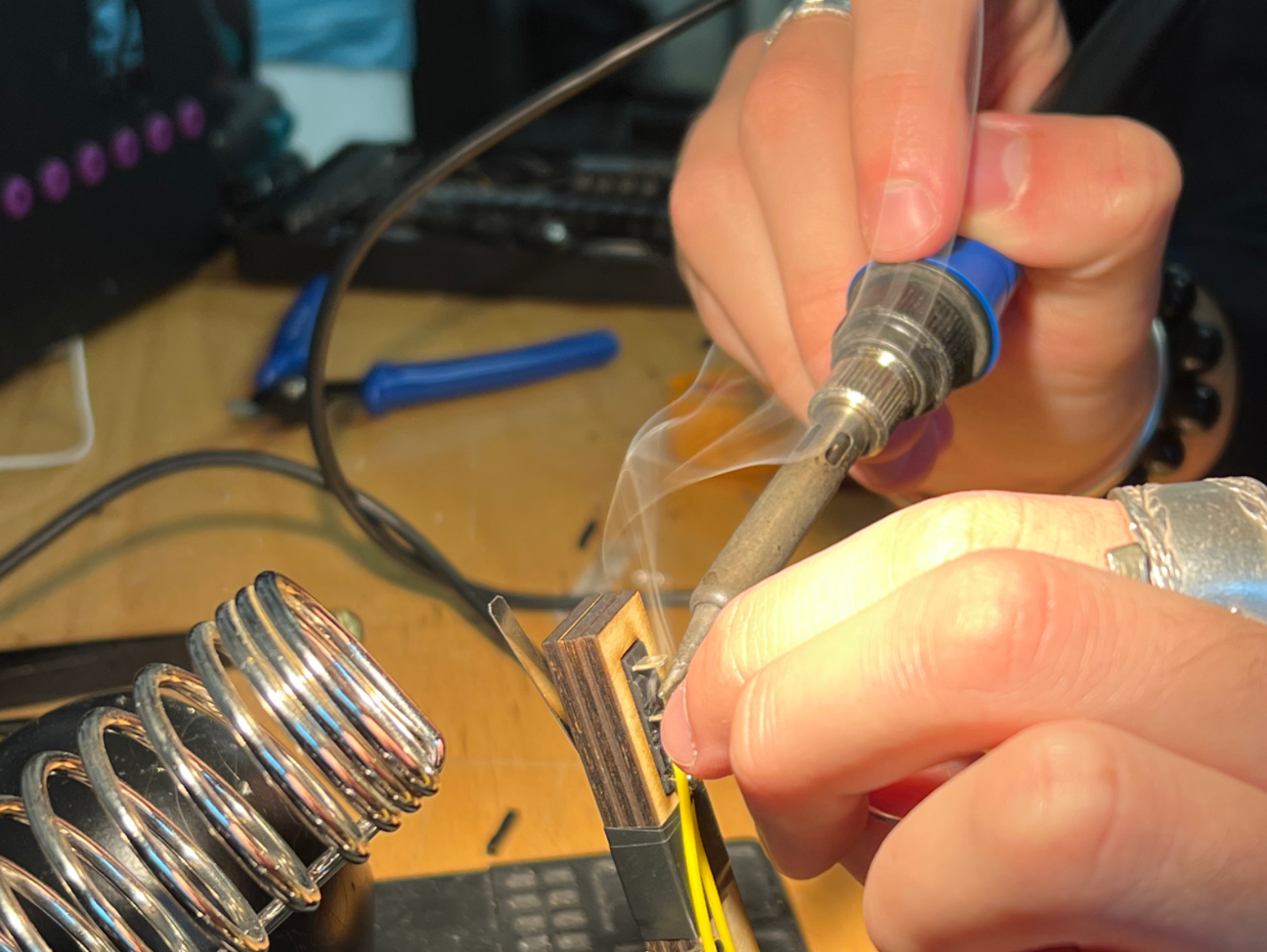

Fabrication Process

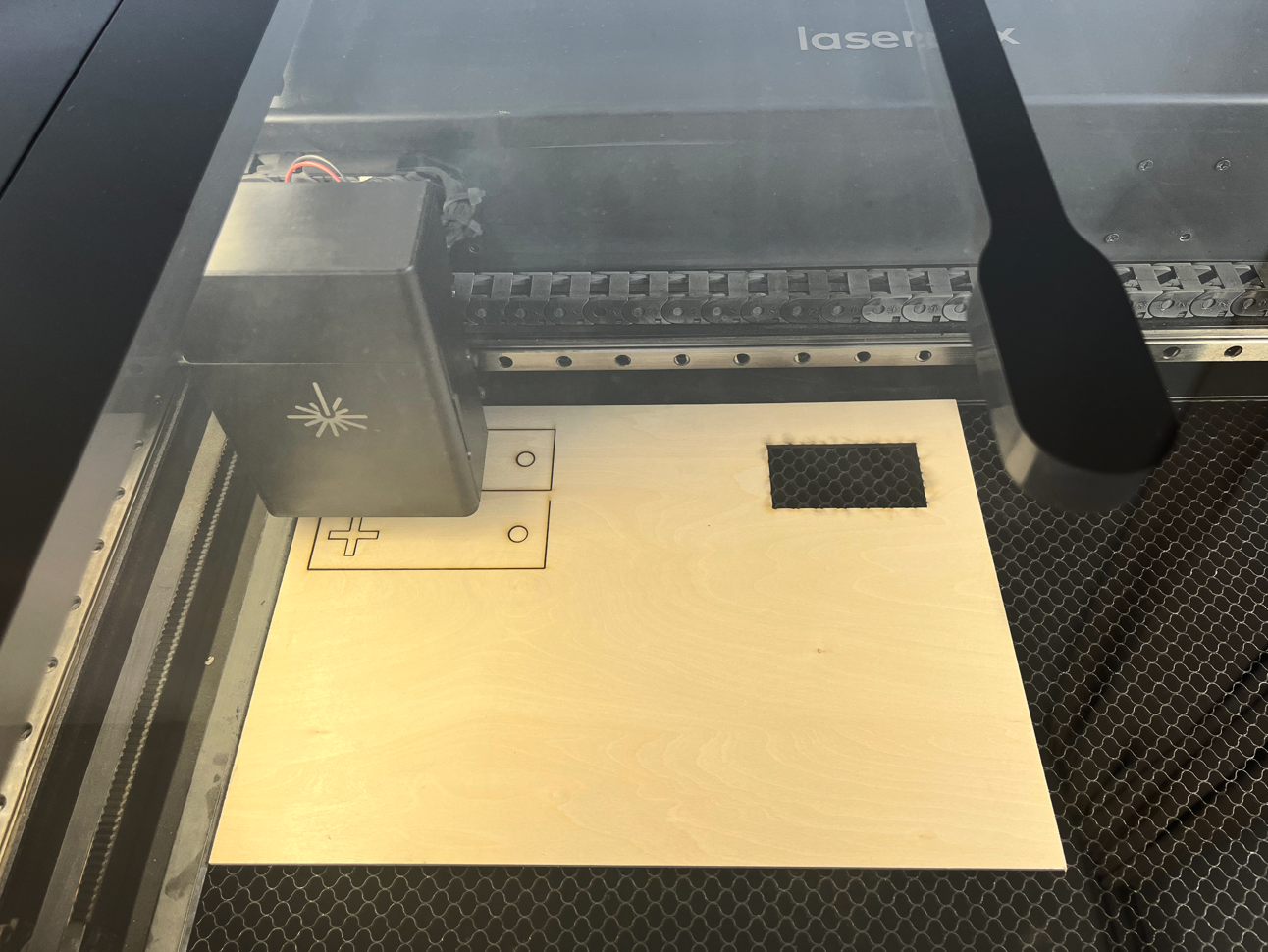

Structural components were laser-cut from wood, providing a modular and easily adjustable construction. This approach enabled rapid iteration and hands-on experimentation throughout the build process.

Mechanical Assembly

The motors were mounted directly onto the wooden structure, forming the physical joints of the drawing arm. Their placement directly influenced movement behavior and drawing characteristics.

Calibration & Reference

A homing sensor was used to define a consistent starting position, ensuring repeatable drawing behavior while maintaining the system's expressive variability.

Radial Movement Logic

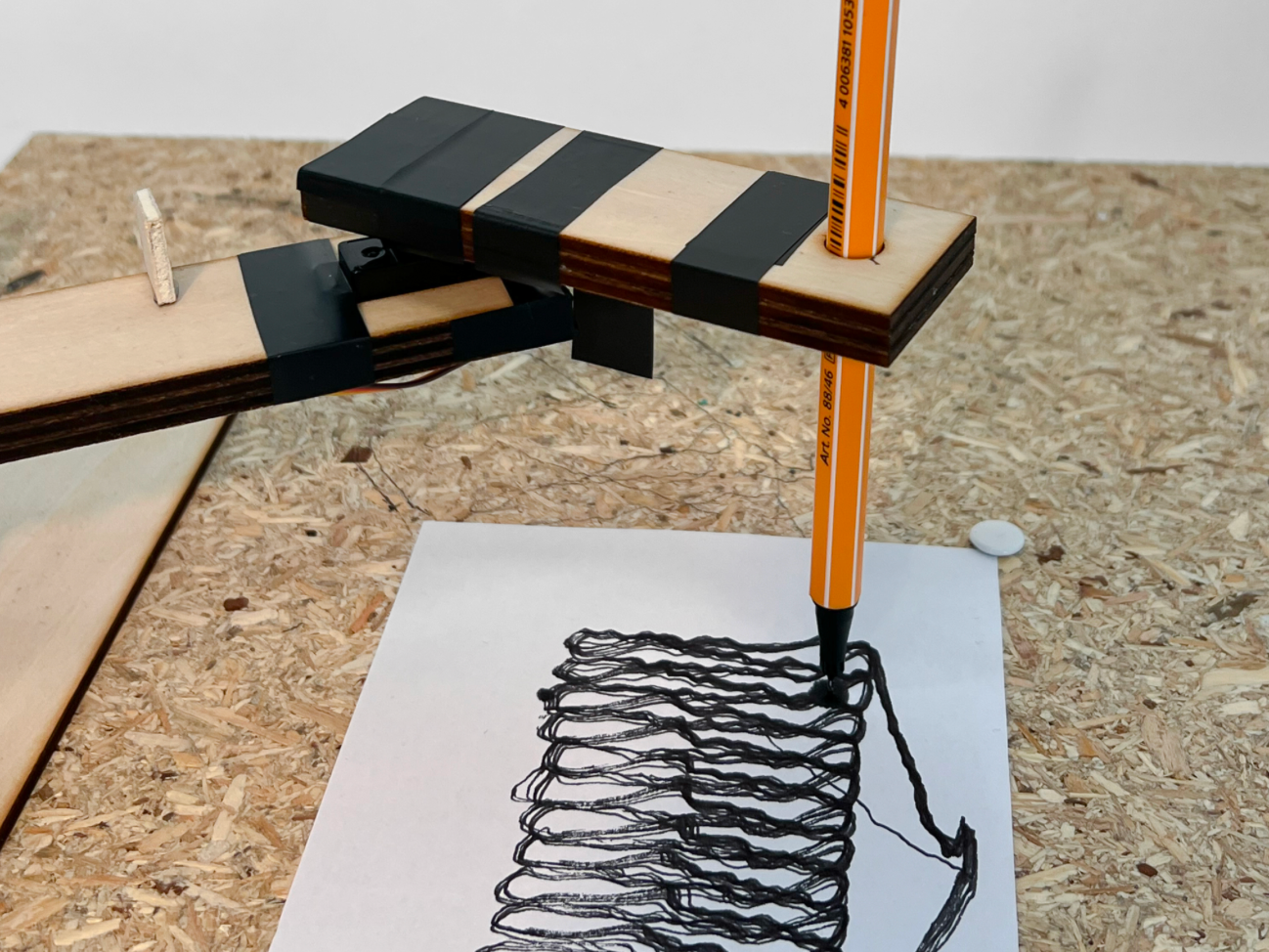

The arm follows radial and curved paths, translating geometric movement into expressive drawn lines. This navigation method emphasizes motion as a core design element.

Functional Prototype

The final prototype combines digital control, mechanical structure, and physical drawing into a compact, functional system—serving as an exploration of how machines can create imperfect, expressive marks.

Learnings

This project demonstrated how mechanical systems can produce expressive, organic results when we embrace imperfection rather than striving for perfect precision.

Working with physical materials, motors, and code taught me the importance of iterative prototyping and the value of hands-on experimentation in mechatronic design.